The brisk winds of change are sweeping across the outdoor sports industry. As the planet’s health takes center stage, there’s a compelling narrative emerging about how circular material innovation is the way forward. The key? Synergy among all the players in the game.

The transformation of the outdoor sports industry is imperative in order to address pressing environmental concerns such as resource depletion and waste generation. Circular material innovation is critical as it enables the industry to reduce its ecological footprint by reusing, recycling, and upcycling materials, thereby minimizing the negative impacts of production and consumption. This transformation is not only essential for safeguarding natural ecosystems but also for ensuring the long-term sustainability and competitiveness of the outdoor sports sector. Examples of circular material innovation include the development of durable and recyclable fabrics made from post-consumer plastic waste, as well as the use of 3D printing technology to create customizable and repairable outdoor gear, reducing the need for constant replacements and reducing waste.

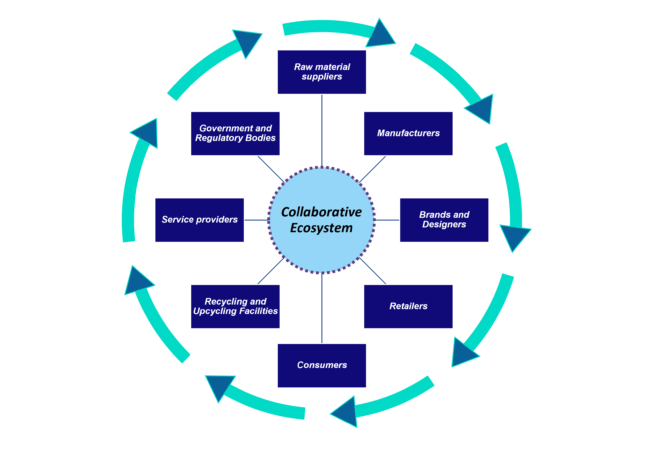

A circular diagram showing interconnected stakeholders: manufacturers, suppliers, consumers, researchers, and policymakers (fig. Circulix / ÆVOLUTION)

Understanding the Collaborative Ecosystem:

Creating collaborative ecosystems for all stakeholders in the value chain of outdoor sports products is essential to drive the transformation of this industry towards sustainability. This synergy involves a wide range of actors, each playing a vital role in the circular value chain.

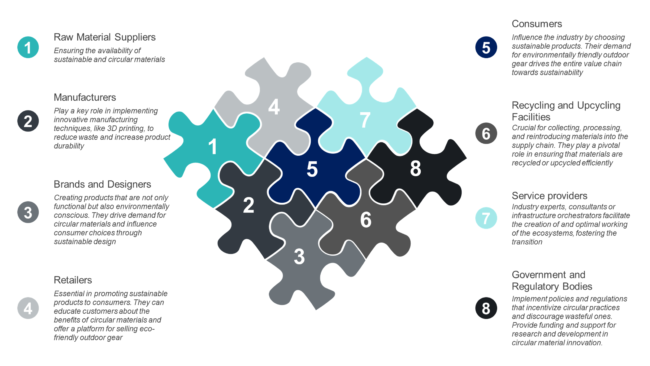

- Raw Material Suppliers: Provide the foundational materials for outdoor sports products, such as recycled plastics for fabric production. Their role is critical in ensuring the availability of sustainable and circular materials.

- Manufacturers: Being responsible for producing outdoor gear using circular materials and processes, they play a key role in implementing innovative manufacturing techniques, like 3D printing, to reduce waste and increase product durability.

- Brands and Designers: Create products that are not only functional but also environmentally conscious. They drive demand for circular materials and influence consumer choices through sustainable design.

- Retailers: Promote sustainable products to consumers. They can educate customers about the benefits of circular materials and offer a platform for selling eco-friendly outdoor gear.

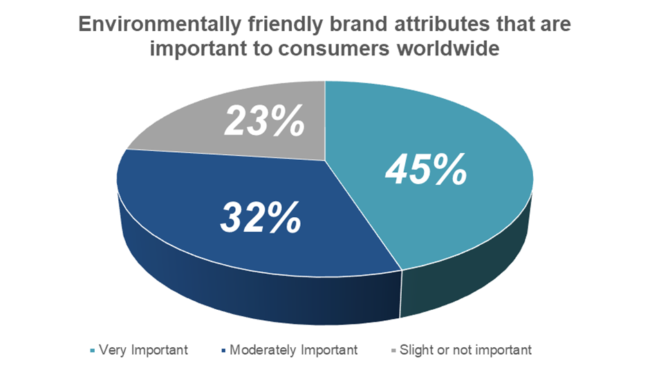

- Consumers: Have the power to influence the industry by choosing sustainable products and supporting brands that prioritize circularity. Their demand for environmentally friendly outdoor gear drives the entire value chain towards sustainability.

- Recycling and Upcycling Facilities: Collect, process, and reintroduce materials into the supply chain. They play a pivotal role in ensuring that materials are recycled or upcycled efficiently.

- Service providers: Industry experts, consultants or infrastructure orchestrators facilitate the creation of an optimal working of the ecosystems, fostering the transition.

- Government and Regulatory Bodies: Implement policies and regulations that incentivize circular practices and discourage wasteful ones. They can also provide funding and support for research and development in circular material innovation.

By fostering collaboration and synergy among these stakeholders, the outdoor sports industry can transition towards a more sustainable and circular model, securing the industry’s long-term viability and innovative business models.

A puzzle of each stakeholder’s contribution (fig. Circulix / ÆVOLUTION)

Accelerating Sustainable Innovation

The collaborative ecosystem approach leads to the creation of disruptive innovations for several compelling reasons:

- Interdisciplinary Perspectives: Collaboration leverages the pooling of wealth of knowledge and expertise. Manufacturers, designers, retailers, and raw material suppliers, can share insights and ideas that may not have emerged within their individual silos.

- Understanding Function in the Value Chain: In a collaborative ecosystem, each stakeholder gains a deeper understanding of their role in the product value chain. This enables them to pinpoint where improvements are needed and identify how their actions contribute to the overall sustainability goals.

- Efficient Gap Bridging: Collaborative ecosystem generates synergies that accelerate the development and adoption of circular materials and practices. Raw material suppliers may develop new sustainable materials, and manufacturers can adapt their processes accordingly, all with input and support from other stakeholders.

- Rapid Adoption: Shared responsibility and a comprehensive understanding of the value chain ensure the optimization of resources throughout the product lifecycle. This not only benefits the environment but also enhances the competitiveness of the industry by reducing waste, lowering costs, and meeting the growing demand for eco-conscious products.

In summary, the collaborative ecosystem in the outdoor sports industry facilitates the identification of gaps, efficient solutions, and rapid adoption of circular economy practices. This holistic approach fosters the emergence of circular business model opportunities. These models not only drive economic feasibility for innovative solutions but also accelerate their adoption within the industry, thus ultimately contributing to addressing pressing environmental concerns and ensuring the long-term viability of the outdoor sports sector.

Real-world Examples

Every theory is only as good as it is put into practice. In the following section, we want to delve into some real-life examples of successful circular material innovation implementations in the outdoor sports industry through collaboration:

The North Face and PrimaLoft: The North Face partnered with PrimaLoft. This collaboration combined The North Face’s design expertise with PrimaLoft’s insulation technology, closing the loop by incorporating recycled materials into new products and reducing waste. Together, they developed the „ThermoBall Eco” insulation technology, which uses recycled materials to create high-performance insulation for outdoor jackets and other gear.

Patagonia and Bureo: Patagonia, a pioneer in sustainable outdoor clothing, collaborated with Bureo, a company specializing in recycling discarded fishing nets. They created the „Patagonia x Bureo” collection, featuring sunglasses and skateboard decks made from recycled fishing nets. This partnership not only tackled plastic pollution in oceans but also demonstrated a circular approach by upcycling discarded materials into durable products.

Eddie Bauer and First Mile: Eddie Bauer, a well-known outdoor clothing brand, partnered with First Mile, specializing in recycling plastic bottles from developing countries. They launched a sustainable outdoor apparel collection made from recycled plastic bottles collected in regions like Haiti, Honduras, and Taiwan. It exemplified how outdoor brands can work with recycling companies to transform plastic waste into high-quality outdoor gear, closing the loop and supporting communities in the process.

Bergans and Spinnova: Another example is the collaboration between the fiber producer Spinnova and the Norwegian outdoor clothing company Bergans. Both companies have created a fully circular subscription-based model that produces fibers from used products made of entirely natural materials. Spinnova fibers with FSC certification from wood and waste are an excellent complement to Bergans’ sustainable development model.”

Vaude i Oechsler: „With the support of the German specialist in 3D engineering and plastic production, Oechsler, Vaude has developed a prototype backpack, Novum 3D, made of TPU, with a back panel created using a 3D printer. Thanks to 3D printing technology, backpack systems made of homogeneous thermoplastic material (TPU) are possible. In combination with other homogeneous materials, the backpack can be easily recycled without the need for complicated separation processes. All elements not made of TPU have been designed to be easily removable.”

These collaborations harnessed their respective strengths, such as design expertise, recycling technology, and sustainability missions, to develop products that not only reduced environmental impact but also demonstrated the economic feasibility of circular business models. The partnerships not only drove product innovation but also showcased the potential for closing the loop in the outdoor sports industry through shared efforts and complementary functions.

With the support of the German specialist in 3D engineering and plastic production, Oechsler, Vaude has developed a prototype backpack, Novum 3D (photo: Vaude)

The Path to Circular Design

The success stories of collaborative circular material innovations in the outdoor sports sector underscore the potential for holistic product concepts with fully integrated circular value chains. Transforming your organization towards a more circular value chain and embark on a sustainable journey – a path, though initially daunting – is entirely achievable through a well-structured approach. Start by adopting Systems Thinking, a holistic perspective that allows understanding the complex interactions within your value chain. This approach helps identify opportunities for circularity and sustainability at every stage.

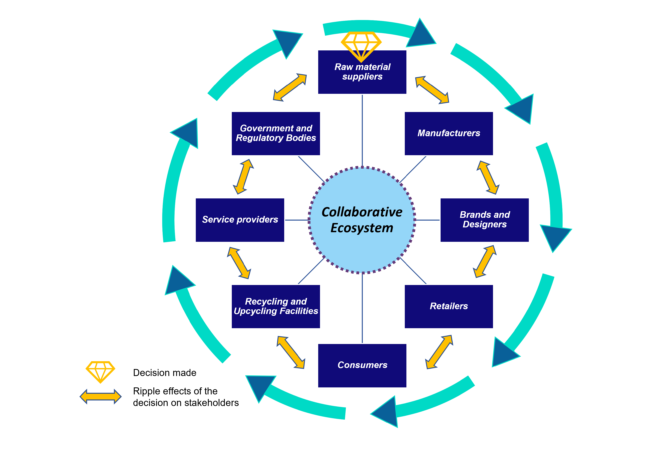

(fig. Circulix / ÆVOLUTION)

To embark on this transformative journey, outdoor brands and companies can consider the following 7-step approach:

- Assessment and Vision: Start by assessing your current practices and setting a clear vision for circularity within your organization. Understand the environmental impacts of your products and envision how a circular value chain can mitigate those impacts.

- Stakeholder Engagement: Identify key stakeholders in your product’s value chain, including suppliers, manufacturers, recycling partners, and NGOs. Collaborate with those whose functions complement your goals and share a commitment to sustainability. What is more, collaborating with experts in Systems Thinking, Material Innovation, and Circular Design provides invaluable insights to navigate the complexities of implementing circular practices effectively.

- Material Innovation and Design: Invest in R&D for circular materials and design principles. Consider investing in Collaborative Research and Development (R&D) projects by partnering with industry peers or academic institutions. This collaboration allows you to pool resources and knowledge, expediting the discovery of innovative materials and sustainable design solutions.

- Product Lifecycle Integration: Implement a closed-loop approach throughout the product lifecycle, from sourcing sustainable materials to recycling or repurposing at the end of life. Create products that are repairable, upgradable, or suitable for second-life use.

- Organizational Change: Foster a circular economy mindset throughout your organization. From C-level executives to product managers, procurement, marketing, and beyond, ensure that everyone understands the importance of circularity and has the necessary expertise in material-driven circular design. This cultural shift will not only drive innovation but also ensure that circular principles are integrated into every aspect of your outdoor sports product development and value chain, making sustainability a core part of your brand’s identity and mission.

- Recognize the pivotal role of consumers in the circular economy cycle. Educate your customers about the benefits of sustainable products and actively involve them in the journey. Their understanding and demand for eco-friendly options can further drive innovation and market acceptance.

- Lastly, establish robust Feedback Loops with all stakeholders, including suppliers, manufacturers, and customers. Encourage open communication and actively seek input to identify areas for improvement. Continuously adapt and refine your circular practices based on this feedback. This holistic approach will pave the way for a successful and sustainable journey in the outdoor sports industry.

(fig. Circulix / ÆVOLUTION; source: Statista.com, 2020)

Conclusion

The future of the outdoor sports industry is circular, sustainable, and collaborative. It’s a journey of shared responsibility and vision. As we look ahead, the collaboration of every stakeholder in the value chain isn’t just an option; it’s a necessity. Together, we can create a brighter, greener future for our planet.

The path to sustainability and circularity in the outdoor sports industry is both attainable and necessary. By embracing Systems Thinking, engaging with experts, investing in Collaborative R&D, educating consumers, and establishing robust feedback loops, companies can drive innovation and create holistic circular product concepts that benefit both their businesses and the environment.

PhD Mateusz Wielopolski, Martin Rafaj

***

For companies seeking guidance in this journey, ÆVOLUTION.tech stands as a leading authority. ÆVOLUTION.tech, a company dedicated to supporting outdoor sports companies in implementing sustainable and regenerative material innovations into fully integrated circular product concepts, excels in connecting its clients with the right stakeholders in the value chain, fostering collaborative ecosystems, and driving transformative change. The authors from ÆVOLUTION.tech are true experts in Systems Thinking, Material Innovation, and Circular Design, boasting extensive networks in Collaborative R&D ecosystems and partnerships with industry peers and academic institutions across Europe.

KOMENTARZE